Printed Labels : Digitally Printed vs Conventional

Share

Printed labels come in many different shapes and sizes and nearly as many different printing methods. Which is the best way to get your printed labels? Read on and we will answer your questions.

You have done the hard work. You have designed and developed the most amazing product; it is going to revolutionise the world. You have the branding sorted and have knocked about many ideas before settling on a design and brand image that reflects your ethos, beliefs, and identity. Now all you must do is get the labels printed and stuck on. Who will you get to print it? (Us, obviously!) What method of printing should you use? How expensive will your labels be? Is there a difference in quality? Should I use the best or the cheapest?

So many questions and never quite enough answers, so let us help. Let’s take a walk through the different options and see if we can simplify what appears to be very confusing. To avoid getting bogged down in lots of detail we are going to discuss this topic in terms of two different types of printing:

CONVENTIONAL PRINTING, the sort of thing that has been around for hundreds of years and involves plates and ink and a lot of mechanics.

DIGITAL PRINTING, it’s been around for about 25 years on a commercial scale. Of which there are lots of types but all doing a similar thing with computer software and electronics.

Anybody who tells you that their method of printing labels is the best, should be ignored. Your requirement for printed labels, will determine which technology to use as each customer, brand and label are different.

Digitally Printed Labels

Digital print is an amazing resource for both the printer and the client. It has some great advantages:

- It does not require plates, so there are cost savings

- It wastes very little material so is more sustainable

- It produces perfect registration every time. This means your design looks flawless and perfectly aligned.

- Every label can be different, ideal for numbering or clever design alternatives

Wow, with all that going on why do we need to look at alternative printing technologies? Well, there are some down sides as well:

- Price per label can be expensive, so short runs are more economic

- It has a limited number of colours, very poor metallic colours and fluorescents

- Some cheaper models struggle with colour matching

Having your printed labels produced digitally is the very “now” thing to do. Digital print is in its element for short runs or long runs with a lot of different sorts. It can handle design and information change very easily and brings real advantages to that kind of work. So, what is the best quantity for digital labels? There are a lot of variables, a good rule of thumb would be for an average size label (76mm x 76mm) up to 20,000 labels per sort, digitally printing would likely be the best route.

Conventionally Printed Labels

That wonderfully messy place of ink and plates and gears and oil. The smell of a conventional printing factory is as evocative as newly cut grass. It has been around for hundreds of years. Of course, it has improved and developed over the years with newer technologies and styles of printing coming and going. The emergence of digital printing has been a driver for significant improvement and change over the last 10 years. We now see flexographic printing presses with very quick change over times and much lower wastage than before. The newer presses incorporate technology like they never have before. The advantages of conventional are:

- Significant cost savings on larger quantities

- Wider gamut of colour

- Better metallic inks and more specialist inks

The disadvantages:

- Plates are a necessary expense as is make ready time and set up material

- No options for variable printing

So How Do I Decide Which Print Process?

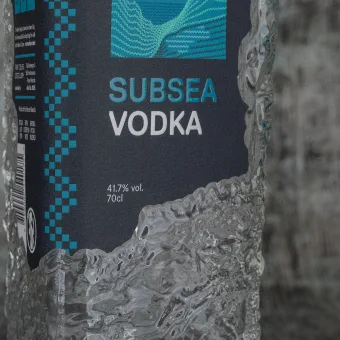

Well, the truth is you shouldn’t. The best label printers will be able to supply your printed labels in both formats. They will have wisely invested in newer technology and still maintained their conventional printing presses. At Label Apeel we can cross match everything we do digitally with everything we do flexographicly. This means that when new brands are just starting out, we can offer them the advantages of short run label printing on digital presses. Then as they develop, and grow we are able to switch them to conventional printing where they are able to bask in the advantages of longer run price savings. These printed labels are a prime example of this.

Your label printer should be someone whose judgement you trust, and you should be guided by them as to how you should print your labels.